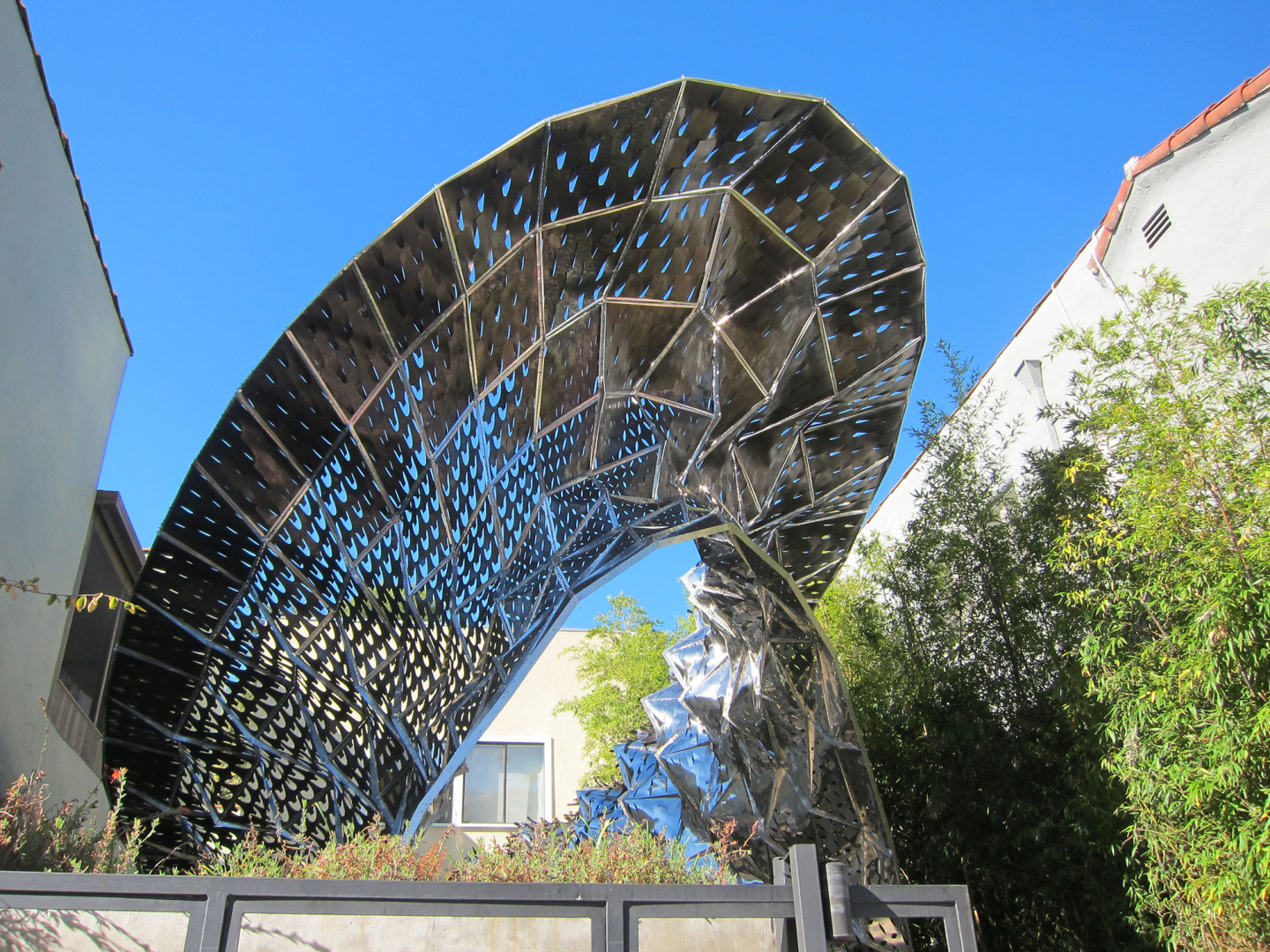

A sun-tracking instrument indexing time and temperature, "Bloom" stitches together material experimentation, structural innovation, and computational form/pattern-making into an environmentally responsive installation. The form’s responsive surface is made primarily out of 14,000 smart thermobimetal tiles, where no two pieces are alike. Each individual piece automatically curls a specified amount when the outdoor ambient temperature rises above 70˚F or when the sun penetrates the surface. The result is a highly differentiated skin system that can smartly shade or ventilate specific areas under the canopy without additional power. For demonstrative purposes, peak performance of the surface is designed for Spring Equinox 2012.

The Intent

The 'Bloom' project set out to demonstrate and test the capabilities of this bimetal in an outdoor laboratory setting over the course of one year. The site's various daily and seasonal changes allow monitoring of three goals: the movement in the surface, the durability of the material and the integrity of a structure over time. This large public installation changes the way people think about architecture vis-a-vis the digital capabilities of design to fabrication; It excites public interest in smart materials vis-a-vis the green revolution and climate change; and it sparks interest in innovative structures vis-a-vis current demands in high performance buildings.

In order to make an impact on the architectural industry, the installation has to embody the three virtues of architecture according to Vitruvius: firmitas, utilitas, venustas. Firstly, the structure must be solid, which, in this case, embodies an optimized shape for a highly efficient monocoque system. Like the matrix of branches on a tree, it is designed to hold its own weight and resist lateral loads flexibly. Secondly, the same large form provides sunny and shaded spaces below for a variety of functions and experimental reconfigurations of public space, part of the gallery's mission. The changing surface controls the temperature of those spaces on hot days. And, finally, the beauty of the piece is derived from its overall form, size and shiny aesthetic. It is difficult to compare the effect of this piece to any other experience. It balances art with technology, an area familiar to architects.

The Process

Dedicated to the process of design from the beginning to end, I wove three different paths of investigations together before arriving at the final form. The two-year process was iterative and exhaustive, and decision-making based on both quantitative and qualitative data, where science meets art. Numerous early studies and prototypes combined with hours of bantering with engineers and collaborators challenged the daily development of the bottoms-up project. The resulting installation is a manifestation of a spiral-like process. The impact on manufacturers, designers, engineers, educators and the general public is clear.

- Material Demonstration

The main goal of this installation is to demonstrate the efficacy of thermobimetal as an exterior building surface with two functions. The first involves the bimetal's potential as a sun-shading device that dynamically increases the amount of shade as the outdoor temperature rises. The size, shape and orientation of the tiles of the tiles are positioned strategically to perform optimally to the relative angle of the sun by use of advanced modeling software. Reliance on digital modeling and physical panel testing prior to final installation is necessary to ensure top performance. The second function for the bimetal is to ventilate unwanted hot air. By optimizing the contortion of individual bimetal tiles, any captured heat would trigger the surface tiles to curl and passively ventilate the space below. In both cases, numerous laser-cutting patterns, solar diagrams, computer analyses and material prototypes were studied, analyzed and tested until the final parameters of the tile cross-shape was set.

- Structural Testing

Composed of 414 hyperbolic paraboloid-shaped stacked panels, the self-supporting structure challenges the capability of the materials to perform as a shell. The panels combine a double-ruled surface of bimetal tiles with an interlocking, folded aluminum frame system. Like the undulation of the surface, the frame, by nature of its folds, is designed to appear on the inner or outer surface at the same cadence of the peaks and valleys. The final monocoque form, lightweight and flexible, is dependent on the overall geometry and combination of materials to provide comprehensive stability. In some areas of "Bloom", the hypar panels are made stiffer by increasing the number of riveted connections, while, in other areas, the panels are deeper to increase structural capability. The intentionally twisted panel shapes aid in the performance of the structure and challenge the digital and fabrication capabilities of parametric design.

- Digital Trials

Finally, the use of complex digital tools continues to challenge the process of design and bring it to new levels in fabrication. Original intentions of using CATIA (Computer Aided Three-dimensional Interactive Application) are set aside early due to the unnecessary size and complexity of the digital models. Instead, Rhinoscript and Grasshopper provide a more streamlined and efficient process. The ability to interface with other softwares like Ecotect and other structural analysis tools confirm the selection. With very few mistakes in the final fabrication files, the use of digital software proves to be an amazingly useful tool in computer-aided manufacturing.

The Value

The impact of 'Bloom' on the design profession, construction industry, academia and general public is a paradigm shift to emergent technologies: It proposes a sustainable, passive method of reducing reliance on artificial climate control systems and, ultimately, waste of valuable energy; It exhibits an innovative structural strategy that values distributed structural stresses and reduces infrastructural needs; And, it demonstrates the power of digital technologies in the design, analysis, and fabrication of complex tessellated surfaces.

Successful completion of 'Bloom' also supports new trajectories of research. Currently, new alloy laminations are being developed in collaboration with manufacturers for durability and for greater deformation characteristics of shape-memory alloys, while other architectural applications, like building screens and bris-soleils, are in production. Because bris-soleils have the potential for immediate application, patterning and tile shape play a large role in performance and in production. The surface pattern, like in 'Bloom', can be customized to optimize curling performance depending on location on the building elevation. Different from their custom-made counterparts, mass-produced building components can also benefit from the insertion of bimetal in its composite systems. In double-glazed panel systems, the bimetal can behave like an automatic shutter system requiring no energy, while in cement blocks, they can allow air to pass through when temperatures are high to make "breezing" walls. In all cases, the tangible contribution to sustainable design is clear. And, the variety of continued research projects is testament to the potential of this smart material in performative building skins. It is a game-changer.

Lead Designers/Researchers:

Doris Sung (Principal Investigator), Assistant Professor, University of Southern California, and Principal, DOSU Studio Architecture

Consultants

Glass Consultant: Ingalill Wahlroos-Ritter, Professor, Woodbury University and Principal, WROAD

Structural Engineer: Matthew Melnyk, Principal, Nous Engineering

Design Team:

Dylan Wood (Project Coordinator)

Kristi Butterworth, Ali Chen, Renata Ganis, Derek Greene, Julia Michalski, Sayo Morinaga, Evan Shieh

Construction Team:

Dylan Wood, Garrett Helm, Derek Greene, Kelly Wong (Core Contributors)

Manual Alcala, Eric Arm, Lily Bakhshi, Amr Basuony, Olivia Burke, Kristi Butterworth, Jesus Cabildo , Shu Cai, Ali Chen, Taylor Cornelson, Erin Cuevas, Matt Evans, Chris Flynn, Renata Ganis, Bryn Garrett, Ana Gharakh, Oliver Hess, David Hoffman, Alice Hovsepian, Casey Hughes, Ross Jeffries, Justin Kang, Syd Kato, Andrew Kim, Glen Kinoshita, Ingrid Lao, Jennifer MacLeod, Max Miller, Mark Montiel, Laura Ng, Robbie Nock, Raynald Pelletier, Elizabeth Perikli, Nelly Paz, Evan Shieh Hector Solis, Raven Weng, Leon Wood, Tyler Zalmanzig

Completion Date:

November 19, 2011

Site:

Materials&Application Gallery, Silver Lake, CA

Funding was generously provided by:

AIA Upjohn Research Initiative, Arnold W. Brunner Award, Graham Foundation Grant, USC Advancing Scholarship in the Humanities and Social Sciences Program, USC Undergraduate Research Associates Program, Woodbury Faculty Development Grant, and in-kind donations from Engineered Materials Solutions.

For video footage of project, please see:

1. Interview with Designer: http://www.youtube.com/watch?v=-Ms5qoMO3gQ

2. BLOOM: Thermally Responsive Surface in Action http://vimeo.com/woodd/bloom-surface

3. BLOOM: Construction Timelapse Video http http://www.vimeo.com/woodd/building-bloom

4. BLOOM: Opening Day http://vimeo.com/woodd/opening-bloom

Doris Sung

In 1999, she opened her office, dO|Su Studio Architecture, and soon received many AIA and ASID awards for her work, including the prestigious accolades of AIA Young-Designer-of-the-Year, ACSA Faculty Design Award, R+D Honorable Mention from Architect Magazine and [next idea] award from ARS Electronica.

Currently, she is working on developing smart thermobimetals and other shape-memory alloys, unfamiliar materials to architecture, as new materials for the "third" skin (the first is human flesh, the second clothing and the third architecture). Its ability to curl when heated allows the building skin to respond for purposes of sun-shading, self-ventilating, shape-changing and structure-prestressing. Her work has been funded by the national AIA Upjohn Initiative, Arnold W. Brunner Grant, Graham Foundation Grant, Architectural Guild Award and USC ASHSS and URAP Awards. Her TEDxUSC talk is available on ted.com.

.jpg)