ENER-G has launched a new range of 'ultra-low' NOx Combined Heat and Power (CHP) systems (50kWe to 230kWe) that are achieving a five-fold reduction in emissions.

The CHP specialist is achieving emissions levels of less than 50mg/Nm3 @ 5% O2 that are sustained across the lifetime of the emissions system of its new CHP range.

This is almost half of the most stringent emissions limit set by both BREEAM and the new Greater London Authority (GLA) Sustainable Design and Construction guidelines. It is five times lower than the more widely accepted limit of 250mg/Nm3 @ 5% O2.

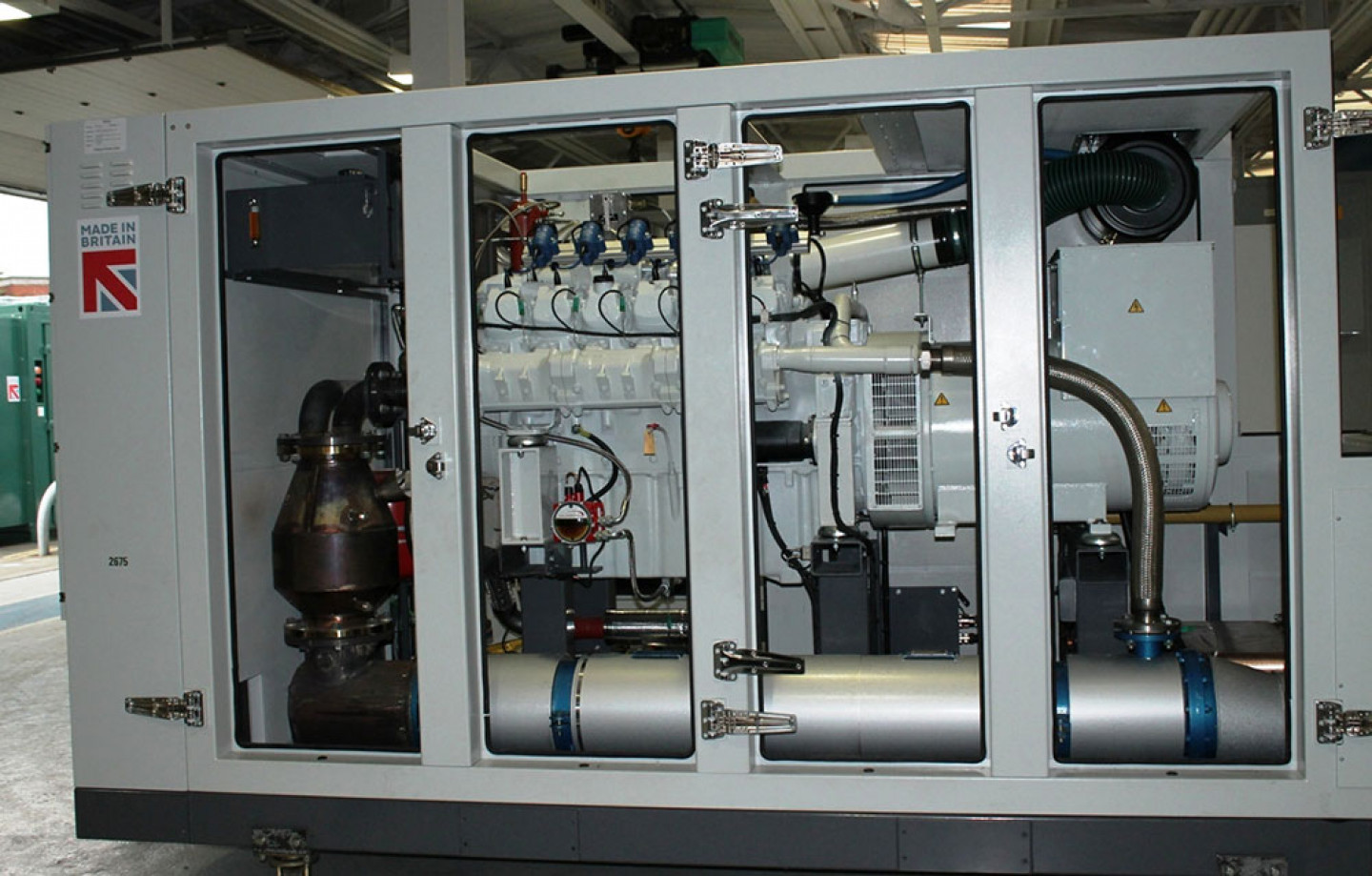

The emissions reduction has been achieved without the need for any expensive external NOx abatement technology and without increasing the size or footprint of existing CHP units.

In addition to exceeding the strict new air quality standards necessary to achieve planning permission in the Greater London boroughs, the low-NOx ENER-G CHP fleet will also qualify for maximum credits under the revised BREEAM standard. It is also fully compliant with the Code for Sustainable Homes and Clean Air Act.

ENER-G's Manchester-based research, development, engineering and manufacturing teams have dramatically reduced NOx emissions by redesigning the internal catalyst area. This has been achieved without increasing the footprint or reducing the overall efficiency of the CHP, while ensuring ample space for servicing and maintenance. The new CHP range has been cleverly reconfigured using 3D CAD modelling technology aligned with BIM processes to fit existing components into the smaller remaining space.

For CHP systems with an electrical output above 230kWe, ENER-G can incorporate external NOx abatement technology, such as selective catalytic reduction (SCR). This can bring the NOx emissions level down as low as 10mg/Nm3, when necessary.

Ian Hopkins, Director of ENER-G Cogen International, said: "Our spark-ignition CHP gas engines, based on naturally aspirated technology with an inbuilt catalyst, were already exceptionally green and clean. We have now further reduced NOx emissions to a level that is far below even the most stringent limit of 95mg/Nm3 @ 5% O2. We believe that we're the only company in the UK that can sustain such a low level throughout the lifetime of the catalyst and without the extra cost and bulk of using external NOx abatement equipment."

He continued: "As the only UK CHP supplier to design, engineer and manufacture our CHP systems under one roof in the UK, we are able to continuously innovate and speedily develop ever cleaner and greener products to meet the emissions standards and carbon reduction targets of the UK and European governments. The new CHP range is attracting strong interest, especially from UK cities striving to improve air quality and looking for a product specifically designed with rigorous UK emissions in mind.

“As the level of emissions testing rises, it is important to make sure that CHP equipment is fit for purpose for its lifetime, not just at the planning and commissioning stages. Emissions performance must be sustained to comply with strict standards. It can be costly, as well as damaging to reputation, if equipment has to be turned off or replaced because of NOx emissions failings."