Walking through the campus at the University of Warwick (UK), your eyes will be drawn to the beauty of the impressive façade of the National Automotive Innovation Centre (NAIC). This prestigious building, officially opened by Prince Charles in February 2020, will host the latest advances in automotive technology for many years to come and deliver the skills needed to keep the UK globally competitive.

Aluminium expanded metal mesh from FILS SpA offered a practical and stylish solution to create the modern and elegant outer skin of this landmark building. FILS SpA is a member company of L Holding, a Group created from the historic and renown brand LonghiGroup, leading manufacturers of expanded metal mesh for the global design community.

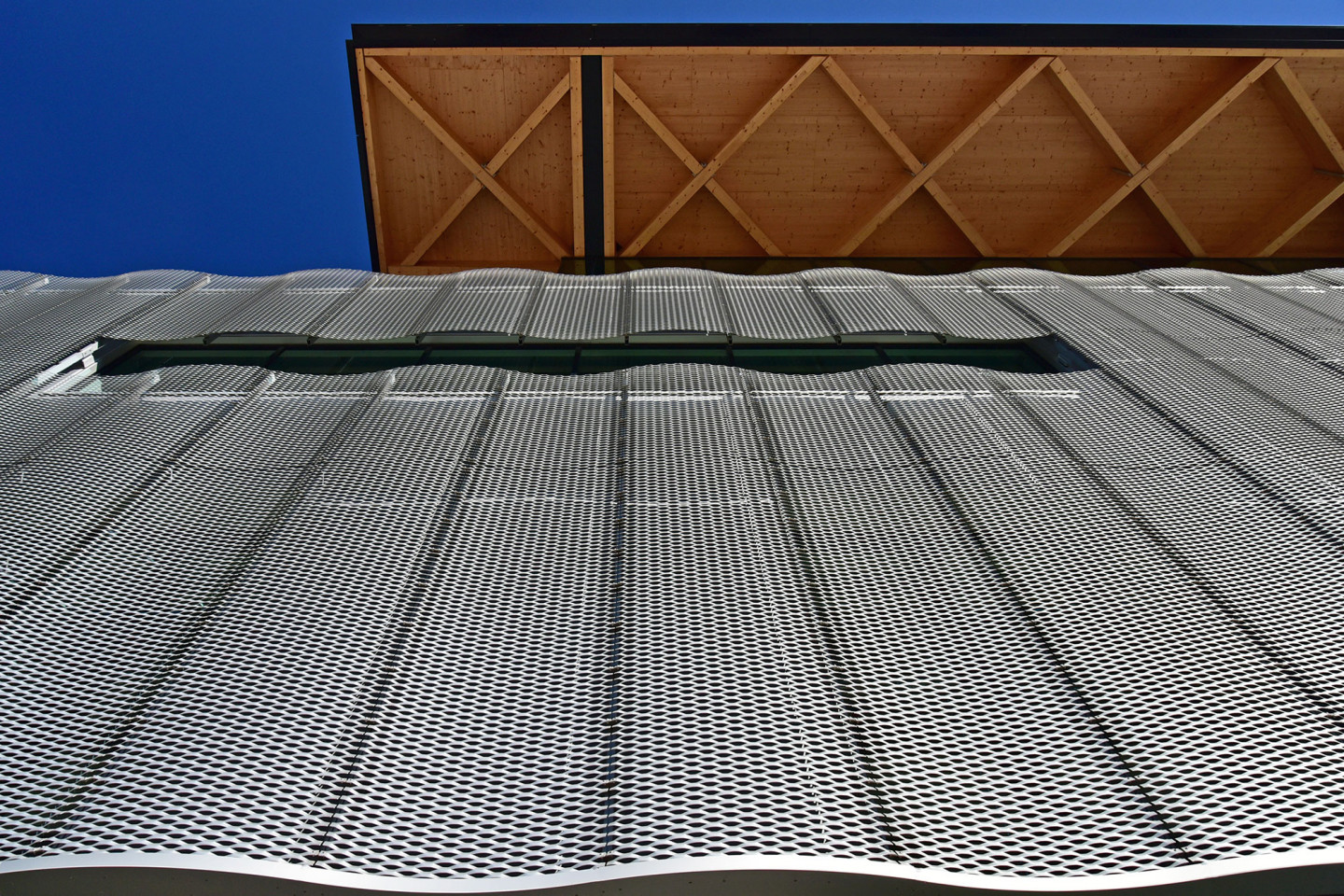

Two mesh patterns with different degrees of transparency are combined into convex and concave panels to give the façade a unique and distinguished curved look which perfectly expresses the concept of engineering and innovation that the NAIC stands for.

Amedeo Aversa, UK & Ireland Market Specialist for the Group, commented: “Architects, Designers, Façade Cladding Specialists, Contractors and Fabricators around the world choose our Expanded Metal Mesh for its unique look, versatility and quality. In speaking with architects and façade cladding specialists, expanded mesh is often preferred to other materials because there is something special about it. It is like a living product which can create iconic façades or enhance the appearance of urban areas and commercial facilities due to its 3D shape, geometry and play of light. The mesh on the NAIC façade is a great example of this and I invite you to see it in real life if you happen to be in the Midlands.”

With 70-year experience in creating and manufacturing mesh for Architecture, the Group from Bergamo in Northern Italy is at the forefront of innovation when it comes to expanded metal mesh. With a range of patterns varying from 50 microns to 800mm eyelet size and an endless array of shapes, all requirements of transparency, ventilation, shading, weight, sustainability and resistance are satisfied. The Group can manufacture finished mesh panels of different sizes and shapes such as curved, angled, wavy, framed or unframed, anodised or powder coated ready for site installation.

“Through myself, we have been offering a local support in the UK for over 10 years and this simplifies the life of local architects and façade specialists. We assist with the project from the designer hand sketch to the production of finished custom mesh panels ready for installation” - continued Amedeo Aversa: “We start by asking one question – what is your design intent? Then we work like a partner trying to transform the architect’s idea into a producible and attractive metal product. I can say that this capability makes us different and successful in the marketplace. After all, the façade is the most visible element of the building where culture and inspiration merge with innovation, technologies and materials; our experience with architectural mesh is beneficial from the early stages of design.”

As a tangible sign of its strong commitment to the UK market, the company has just launched a new UK dedicated catalogue with the most up to date collection of projects completed in the UK and its innovative solutions. Click here to download.

To request technical information or mesh samples please call: (UK) 07590 984722 or email: amedeo.aversa@longhigroup.com