IG Masonry Support worked closely with KDS Architects and St George’s Developments to provide an offsite solution to achieve the brick detailing on the 10.2 metre wide bridge. The panels were delivered to site in the heart of London and installed on the same day providing a time efficient solution on this project.

The Chelsea Creek Development encapsulates the iconic maritime history of the London Docks. Providing high specification apartments in a beautiful waterside location, the project features a series of waterways that create elegant water gardens throughout the development. A 10.2m span bridge would be required to span the breadth of the water to connect walkways. IG Masonry Support can produce brick slip components for a range of applications and were approached for the provision of four brick clad panels to achieve the brick detailing on each side of the bridge.

The Challenge

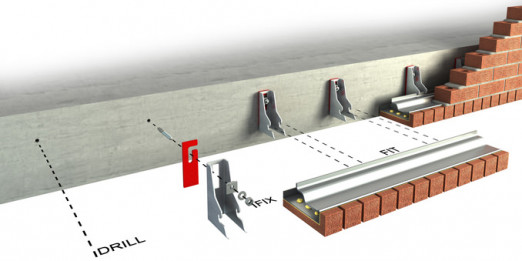

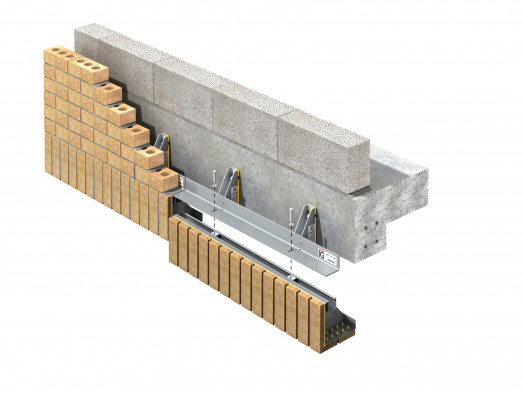

IG Masonry Support was tasked with creating a 10.2m span brick slip bridge panel to span the breadth of the water for the Chelsea Creek project. The system would consist of four brick clad panels, two panels for each side of the bridge, to accommodate the brick detail required, including a 440mm deep soffit. Extensive tests had to be carried out to ensure longevity and performance of the bridge, including freeze-thaw simulations and weathering pull tests on the brick slips bonded to perforated steel. Many factors were considered during the design stage, including the systems capability to allow floodwater in and out of the hollow steel frame in the event of rising water levels. To ensure resistance to corrosion and avoid rust, IG manufactured all components from 316 Austenitic Stainless Steel.

The Solution

Due to the sheer size of the installation, the brick slip bridge panels were produced and delivered to site in two separate components and fixed together onsite through bolt connections. Situated within the heart of London, delivering components in two parts also made logistical sense. The panels were delivered and installed on the same day, lifted in by crane and bolted into place. Matching the brick requirements on site ensured that the bridge blended seamlessly with already constructed brickwork. IG’s prefabricated panels ensured no formwork was required to create a deep brick soffit on the underside of the bridge, streamlining the process and saving considerable time on-site. The bridge at Chelsea Creek demonstrates IG Masonry Support’s design creativity when it comes to bespoke brick slip components, helping to achieve even the most complex architectural designs with modern off-site building practices.

Visit the IG Masonry Support website to read our case studies: http://igmasonrysupport.com/casestudies/