McTaggart Construction came to IG Masonry Support Systems to provide solutions for 6 blocks of flats, all with Brick Slip Soffits and long spans. Prior to contacting us, the proposals were based around heavy concrete lintels, adding considerations on site that could be solved when using our solution.

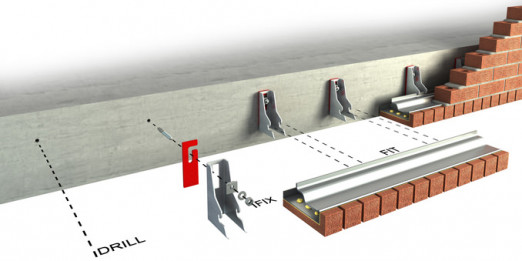

The large balconies had Brick Slip Masonry Supports, designed to enable easy installation. Brick Slip Lintels were designed for all of the other openings.

This solution, manufactured off-site, was lighter and assisted with time and safety on site.

Every Brick Slip lintel is a bespoke product. IG Masonry Support’s engineers worked with the client’s architect to assess the structural loadings and design a suitable lintel which would achieve the brick pattern required to match the older properties.

IG Masonry Support Systems handled the brick cutting and adhesion process, produced in a factory controlled environment utilising patented perforated galvanised steel system and a BBA approved hi-performance adhesive.

Fully assembled lintels were delivered to site, ready for installation and final pointing.