The ROCKWOOL solution has provided the perfect answer to ensure that the new roof retains sound effectively within the stadium and helps create an unforgettable spectator experience at every event.

The Olympic Stadium, centrepiece for many of the most memorable moments of the London 2012 Olympic Games, is looking forward to a new future as the permanent home of Premier League football club, West Ham United.

A 99 year tenancy, running from 2016, has been granted to the club on the proviso that the Stadium is modified to suit its new tenant's needs. The new venue also hosts five matches during the Rugby World Cup 2015 and will become the new national competition Stadium for athletics in the UK as well as hosting elite international athletics events and other sporting, cultural and community events.

E20 Stadium LLP, a joint venture between the London Legacy Development Corporation (LLDC) and Newham Council, was specifically set up to transform, manage and complete the Stadium's renovation works, with a key element of the project involving the extension and upgrading of the roof system to cover increased seating capacity.

Main contractor, Balfour Beatty is leading the conversion of the Stadium into an all-round multi-use venue which will deliver a lasting sporting, cultural and commercial legacy in East London.

The Challenge

The primary purpose of the new roofing at the Olympic Stadium is to provide all-weather shelter over a new area of retractable seating. This seating can be installed and removed over the running track to meet the different capacity and functional requirements of the Stadium.

Once reconfigured, the Stadium's 44,000sqm cable net roof, 84 metres wide at its deepest point, is set to be the largest cantilevered roof in the world covering every Stadium seat.

Acoustic performance was a key challenge on the project. Building Envelope contractor, Lakesmere was tasked with ensuring that the new roof counteracted the risk of noise break out to the surrounding areas from the stadium and enhance the clarity and intelligibility of PA systems.

At the same time, the roof acoustics were required to help deliver a fantastic spectator experience, by effectively retaining and reflecting crowd noise within the Stadium.

The ROCKWOOL Solution

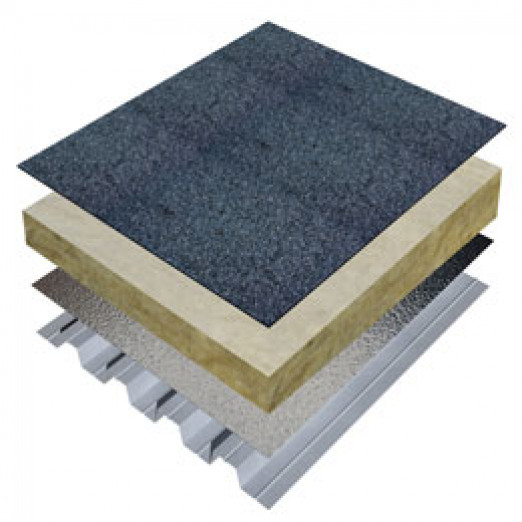

Lakesmere specified and installed an acoustically insulated membrane roof, featuring ROCKWOOL HARDROCK® Multi-Fix (DD) and ROCKWOOL Acoustic Infills.

HARDROCK® Multi-Fix (DD) is a versatile flat roof board solution which carries with it exceptional acoustic and fire resistance properties. Ideally suited to this type of metal deck application, HARDROCK® Multi-Fix (DD) can be securely installed within mechanically fixed systems with just a single fixing. It also provides excellent acoustic performance, managing airborne sound levels and controlling sound reverberation without the need for any additional layers, so saving time and cost.

The HARDROCK® Multi-Fix boards were tightly butt-jointed and mechanically fastened to the structural deck with the Fatra FF852 Fixing Discs. The roof system was completed with the installation of the Fatrafol FF810 PVC-P waterproofing membrane which provided fast installation and long term durability.

At the Olympic Stadium, Lakesmere used approximately 27,000m2 of 50mm HARDROCK® Multi-Fix (DD) together with 96,000 linear metres of ROCKWOOL Acoustic Infills. Designed and tested for use within ROCKWOOL HARDROCK® roof systems, these trapezoidal shaped insulation infills provided a combination of optimised density, fibre direction and excellent fit to satisfy the required levels of sound absorption.

Prior to its installation and supply, Lakesmere carried out specific acoustic testing at the SRL to ensure the product met all specific acoustic requirements.

"ROCKWOOL proved very supportive during the pre-installation testing and provided all the materials necessary to assess product suitability," says John Bosley, Project Manager at Lakesmere. "With a project of this size and stature, it was essential that the roof insulation delivered on the required acoustic performance. As an added bonus, the ROCKWOOL solution has also been quick and easy to install and offers a very reliable, long lasting solution."

All ROCKWOOL products for the project were supplied by SIG Insulation, who was able to meet stringent health and safety, delivery and logistical demands set out by the main contractor.

Visit the ROCKWOOL website to learn more about the products and solutions offered www.rockwool.co.uk