Netheridge Swing Bridge in Gloucester is a key point of entry into the city, carrying traffic over the Gloucester to Sharpness Canal. Opened in May 2007, it’s a 40 metre-long steel twin box bridge which forms part of the Gloucester South-West by-pass. After 10 years of heavy use the bridge was in urgent need of re-surfacing – some of the potholes almost went through to the deck of the bridge.

The work had to be carried out as quickly as possible, with minimum disruption to traffic. The client was Gloucestershire County Council and Amey the principal contractor. RAB Associates, the highways repair specialist, was sub-contracted to carry out the resurfacing work. RAB came up with an innovative proposal to combine a bituminous waterproofing layer with a waterproof bituminous surface course, and chose IKO PLC as its manufacturer partner. In its press release announcing the project, Gloucestershire County Council said this would “reduce the need for future repairs and road closures – making life easier for motorists and reducing congestion in and around Gloucester.”

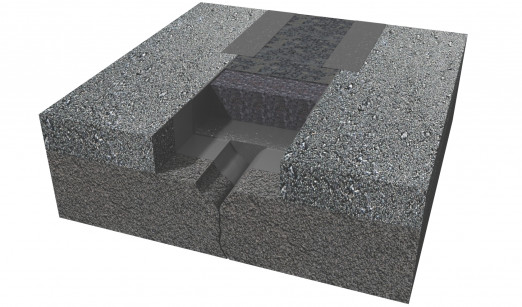

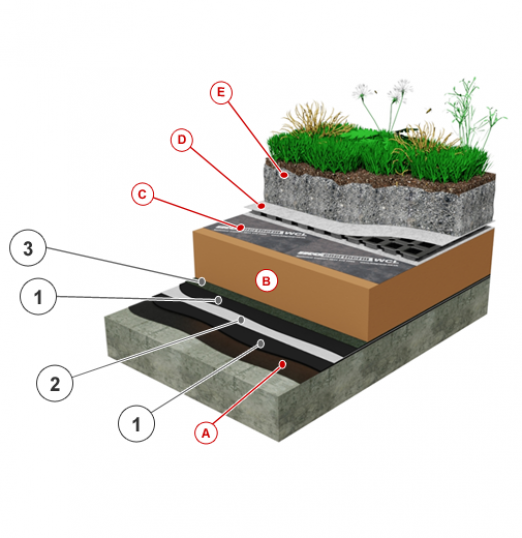

Andrew Skipper, Director of RAB Associates, explains: “Our remit was to resurface the bridge with a high quality material which would last well and provide a smoother, safer and better surface. As far as possible we had to avoid disruption to traffic, so we scheduled the work to keep the flow of traffic going in both directions, closing lanes rather than shutting the whole bridge. Fortunately we didn’t have to stop work to open the bridge for canal traffic – although one of our operatives was trained to open it if necessary! We decided to use IKO Permatrack PSB as a bituminous waterproofing layer, combined with IKO Permatrack Bridge Surfacing as the waterproof bituminous surface course. This meant we were able to install both the waterproofing and surface course as a single contractor, saving time and disruption for business and the public, and money for Gloucestershire County Council. IKO Permatrack is specifically designed to cope with movement so is ideal for flexible structures, such as bridges, to prevent cracks and potholes appearing, so it should reduce the need for future repairs and road closures.”

Another major factor in RAB’s choosing IKO products was the manufacturer’s ability to supply large quantities of mastic asphalt as ‘ready to lay’ hot charge material with up to 18 tonnes in a single delivery. This saves time for the contractor as deliveries can be scheduled for immediate use, which in turn saves money and reduces disruption to the minimum. Wayne Perrin, Business Development Manager at IKO, comments: “We rose to the challenge and safely delivered hot charge ‘ready to lay’ material, on time, in large quantities when and where required by RAB Associates, from our manufacturing plant to the point of laying: a distance of 120 miles!” Delivering material this way is better for the environment too as there’s no secondary heating and melting needed on site, making it a much safer and quicker process. Environmental impact is a major consideration on all projects. IKO has ISO 14001 for environmental management and BES 6001 for responsible sourcing. Improving the environmental performance of our factories and products are issues that are addressed at all stages from manufacture to delivery; recycling raw materials, reducing packaging, cutting energy and water consumption and monitoring logistics.

RAB has completed several similar projects using IKO Permatrack. Andrew Skipper adds: “IKO Permatrack is the perfect solution to installations like these. It’s reliable, quick to lay and because it’s specifically designed to accommodate movement in structures it helps prevent cracks and potholes appearing. It’s economical too. The mastic asphalt acts as a waterproof surface course and gives a voidless surface without the need for any compaction, so it isn’t affected by water ingress or freeze/thaw damage.”

The contractor also opted to use 6mm pre-coated chippings, broadcast into the still molten IKO Permatrack Bridge Surfacing, instead of the more usual 14/20mm chippings. The smaller chippings are easier to install and provide better texture depth and skid resistance with a better spread and an even surface. This surface lasts longer and avoids future disruption to traffic into the city.

Councillor Vernon Smith, Gloucestershire County Council’s cabinet member for Highways and Flood, said: “This major route into and around the city centre is an important asset for our city, connecting thousands of residents, commuters and visitors to Gloucester’s shops and historic centre every day. It’s crucial that resurfacing and repairs are carried out in good time in order to keep our county moving.” The project was completed on time and within budget, in February 2017, with minimal disruption to the traffic flow.

A video of Netheridge Swing Bridge resurfacing project can be seen at: https://youtu.be/_gjgK2pmNzs

.jpg)

.png)

.png)