Leading ventilated façade system manufacturer, Shackerley, has become the first cladding supplier in the UK to develop an anti-fragmentation meshing process that has been certified as Class A1 to BS EN 13501-1 for fire safety. The innovative new process means that the company can now provide SureClad® cladding systems that meet the highest standard of fire resistance for back-meshed non-combustible cladding material.

The new meshing system builds on Shackerley’s fire safety credentials and the company’s solutions-driven approach to helping specifiers comply with legislation on the mandatory use on non-combustible cladding for residential buildings of 11m or more. Shackerley’s SureClad® mesh-backed Ceramic Granite and Natural Stone façade panels are now all classed as A1 for fire safety. The company’s existing meshing process and its SureClad® Engineered Stone system are certified as Class A2-s1-d0 when tested to BS EN13501-1, which also complies with cladding legislation for high-rise residential buildings.

With the development of the new A1-certified meshing system, Shackerley can now offer specifiers an entirely A1 system across its SureClad® Ceramic Granite and Natural Stone ranges, anticipating potential future legislation and offering a best-in-class solution for insurers and mortgage companies.

Brian G Newell, founder and chief executive of Shackerley explains: “Fire safety has, quite rightly, become a main priority for specifiers since the Grenfell tragedy. It’s clear that, though current legislation on non-combustible cladding is focused on residential buildings, fire safety has become a key specification criterion for all buildings; not just for specifiers but also for developers, investors, insurers and mortgage companies.

“All Shackerley façade systems and finishes are non-combustible, but we wanted to ensure we could offer anti-fragmentation, mesh-backed systems, that are completely A1-certified. Developing a meshing process that has been tested as A1 to BS EN13501-1 enables us to do that.”

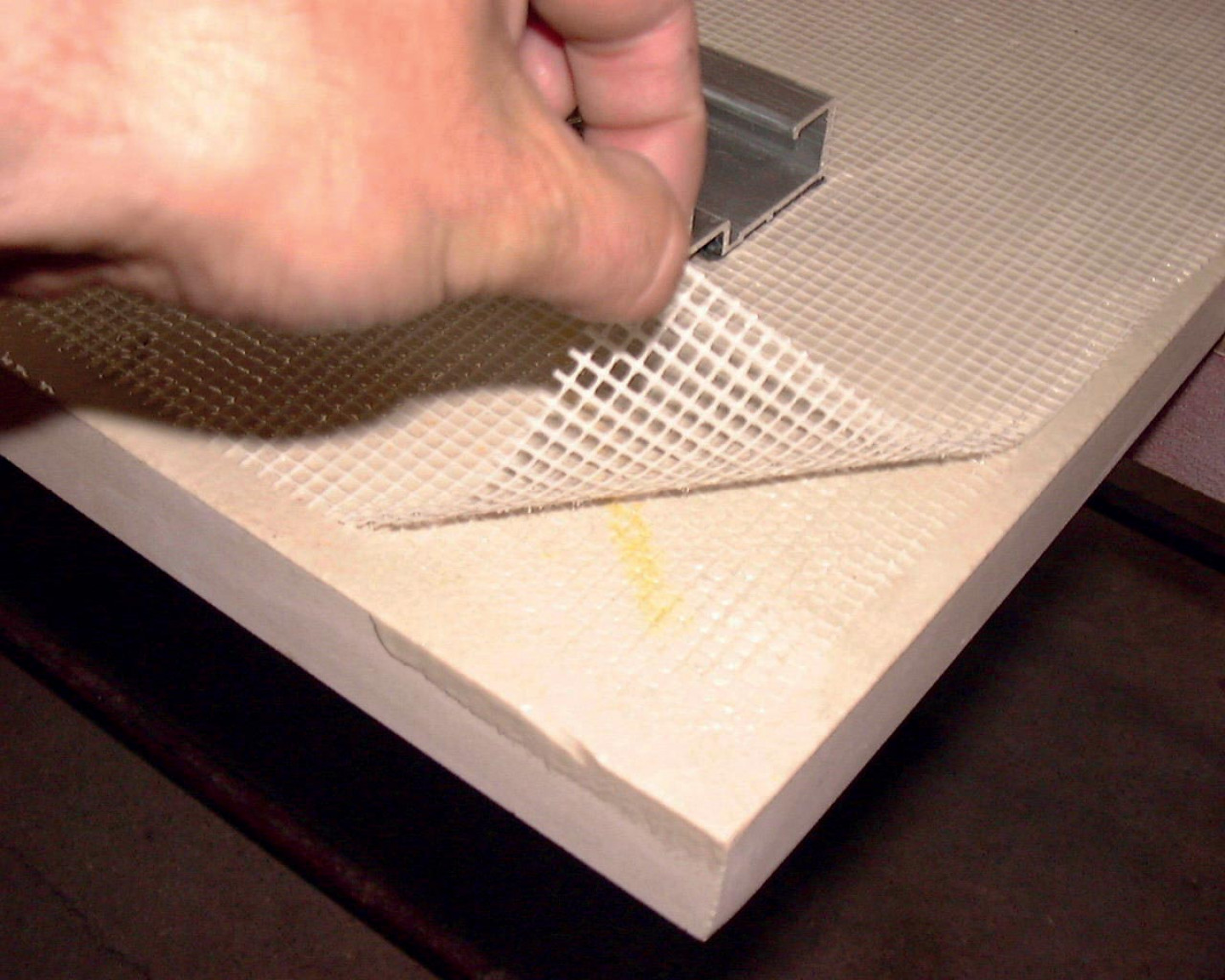

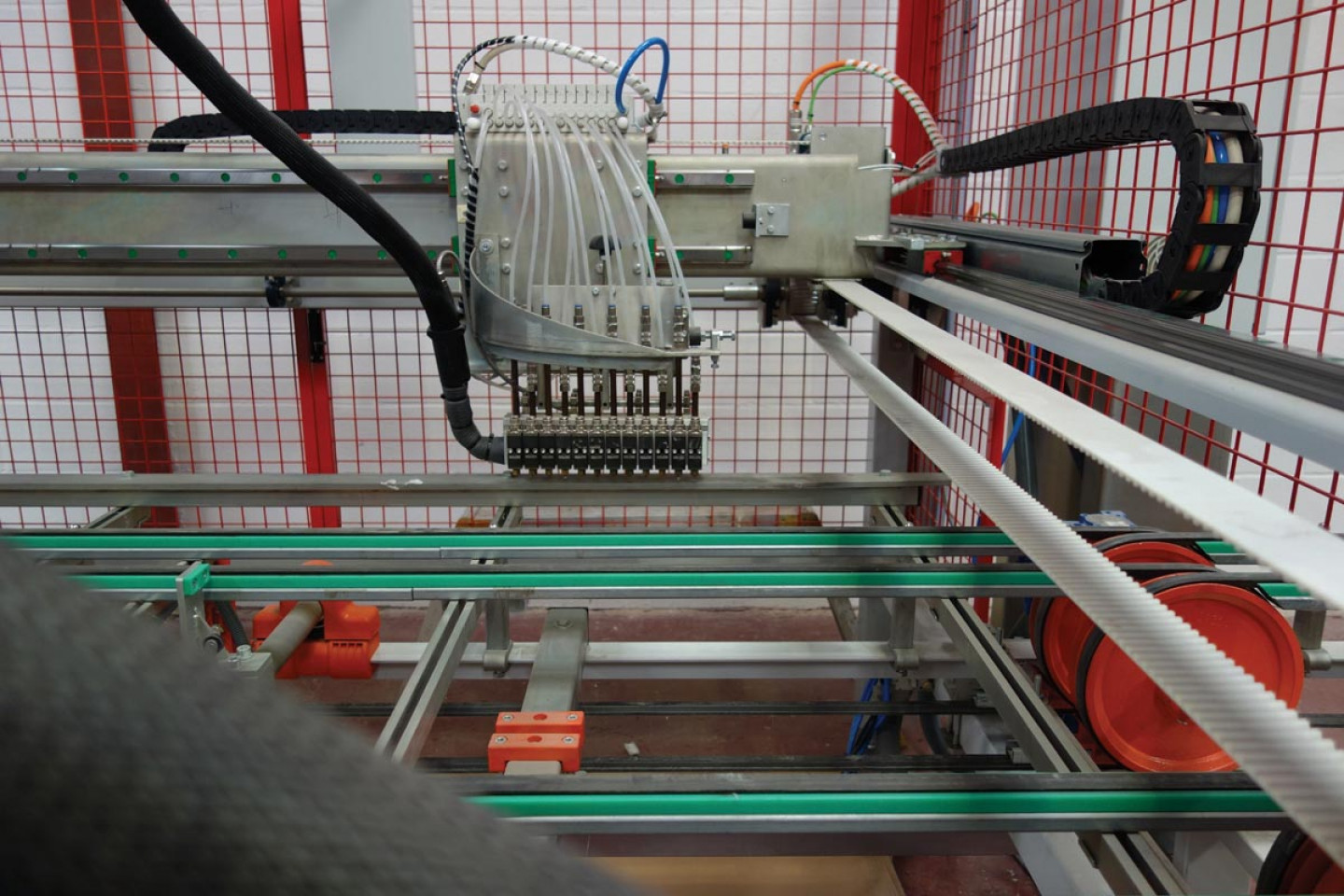

The mesh is applied to the rear of cladding materials at Shackerley’s ISO 9001- accredited production facility in Lancashire prior to fabrication of the panels. It provides an important safety measure for SureClad® installations by preventing fragmentation of installed panels due to catastrophic impact, thereby protecting against the potential for any falling debris.

Brian adds: “Safety is important throughout the lifecycle of the cladding system, including transportation to site, installation and service life. Our systems not only prioritise fire safety but have also been seismic-tested and protected with the anti-fragmentation mesh, ensuring that specifiers and developers can be completely confident of safety with SureClad®, alongside aesthetics and performance.”