Vaeplan has built up a solid reputation as producer of high-end VAE (Vinyl Acetate Ethylene) synthetic single ply roofing product of which the durability has proven itself in practice. This technology is based on a unique mix of copolymers, the acrylic polymers being chemically bonded to the vinyl structure. This molecular combination of vinyl with acrylic polymers results in a highly flexible and stable rubber copolymer.

Key Features & Applications

- Because of its vapour permeability, the risk of condensation problems in comparison with other synthetic membranes is astonishing - 5 to 15% times less. This comes in handy if the use of the building changes. The same advantage also applies in the case of captured humidity in the build-up during installation - it dries out up to 15 times faster.

- Vaeplan is entirely recyclable. Any excess start-up material is completely re-introduced in the production of new batches. Vaeplan is especially suitable for the collection and re-use of rainwater.

- The specific composition on a Vinyl Acryl Ester base and the copolymerisation techniques guarantee a durable flexibility so no ageing will occur due to plasticizer migration. Independent durability studies on 30 to 40+ year old roofs have proven this.

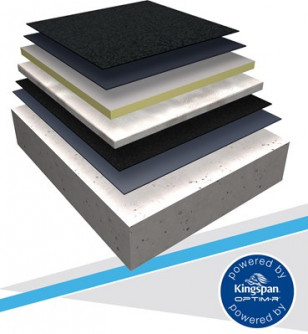

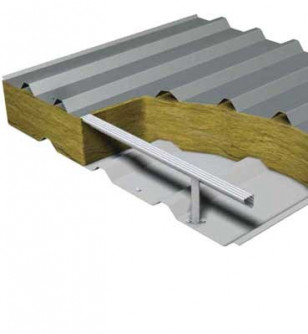

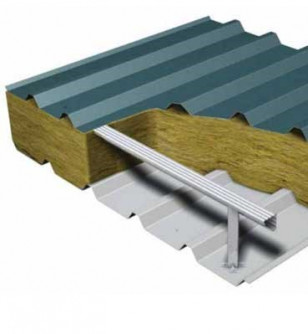

Membrane & Insulation

- Contrary to other synthetic membranes, Vaeplan is not only resistant to oils and greases etc but also to a long list of chemical products. The homogenous composition of the membrane combined with the polyester lining gives it a high resistance to physical impact and other possible damages and costs.

- Insulation choice includes PIR and mineral wool to suit specification and U-value parameters.

Installation & Maintenance

- Installed by a nationwide network of Alumasc Registered Contractors.

- A simple and fast application method which consists of two welding techniques: hot air & cold welding.

- Vaeplan V can be applied using a variation of methods such as loose laid, bonded, mechanically fastened.

- The highly reliable welds are as strong as the material itself. During the welding, either with hot air or with the cold welding agent, a molecular fusion takes place in the overlap: the best guarantee for a reliable and long-lasting waterproofing of the joints.

https://www.alumascroofing.co.uk/ - Alumasc Roofing: leading supplier of innovative, high-performance flat roof systems, waterproofing and green roof systems