The Safe2Torch initiative – aimed at reducing the risk of roof fires when installing waterproofing – is just over six months old.

So what does it mean to contractors’ working methods and what difference does it make?

The use of gas torches has been around for many years since the introduction of “torch-on membranes” and it was always seen as quick and reliant. However, the roof fires that have happened in recent years were more down to drying the roof than about problems associated with a waterproofing product itself or through competency of the personnel working on a roof.

Contractors tend to be habitual and often don’t change their ways of working until something goes wrong and the Safe2Torch campaign has highlighted the issues of safe application of any waterproofing systems, not relating only to membranes but also the risk throughout the installation process.

The recommended approach under Safe2Torch is to identify potential risks at survey stage and identify torch-free solutions for installation. This is about putting safety first, right from the design stage. So now, many contractors are re-thinking the ways to plan work, how operatives are installing systems and considering safe equipment and types of products to use in those areas while specifying products that are suitable for Safe2Torch applications.

Identifying and managing the risks on the roof

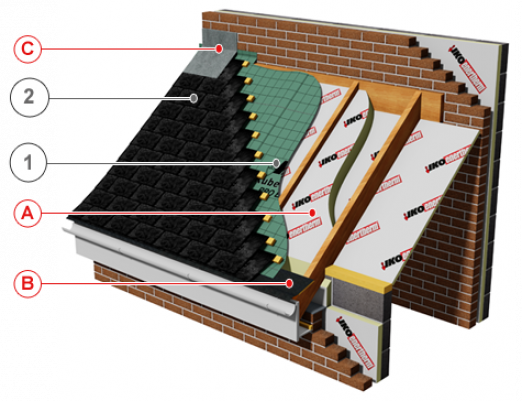

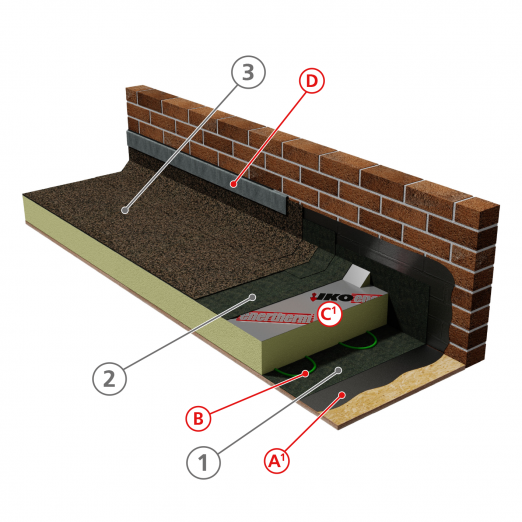

To understand the risks, contractors need to conduct a risk assessment and create a method statement that will work in accordance with those risks. While responsibility for this depends on how the work is tendered, a contractor doing their own work will have to carry out their own risk assessment and method statement to ensure safe working. Risks that need to be top of the list include combustible materials, pitched roofs, cladding and breather membranes – in other words, anywhere you don’t want to put a flame!

Also, for the contractor, it’s about how to sequence works in a way that will minimise risk in the installation process. For example, a contractor generally finishes off the with flashings – and you need a different mind-set to work on a particular area with cold-applied products.

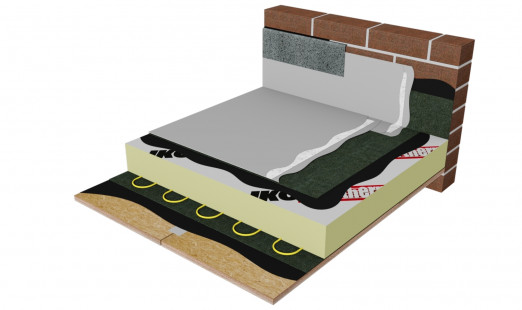

Effective torch-free solutions

When it comes to replacing the torch-based drying and installation methods, new technologies are breaking through for cold and liquid-applied products. What’s now available to contractors and installers goes from cold-applied, self-adhesive products to liquid-applied applications of a waterproofing solution. IKO has created a wide range of cold applied products including IKO Safestick, IKO Mach One, IKO easyseal, high performance liquid adhesives and the IKO Ruberseal EPDM membrane.

The Safe2Torch campaign is helping to educate the roofing industry about the safe use of gas torches for roofing works. IKO, a leading manufacturer in the design and specification of waterproofing membranes, is putting its support behind the campaign. In the end, being aware of roof fire risks is the beginning of minimising those risks.

.jpg)

.JPG)